High-Entropy Alloys with Bidirectional Transformation Induced Plasticity

What is a Bidirectional Transformation ?

We observed a new mechanism that allows load-driven formation and permanent refinement of a hierarchical nanolaminate structure in a novel high-entropy alloy containing multiple principal elements.

This is achieved by triggering both, dynamic forward transformation from a faced-centered-cubic γ matrix into a hexagonal-close packed ε nanolaminate structure and the dynamic reverse transformation from ε into γ. This new mechanism is referred to as the “bidirectional transformation induced plasticity” (B-TRIP) effect, which is enabled through a near-zero yet positive stacking fault energy of γ. Modulation of directionality in the transformation is triggered by local dissipative heating and local micromechanical fields. The simple thermodynamic and kinetic foundations for the B-TRIP effect render this approach generally suited for designing metastable strong and ductile bulk materials with hierarchical nanolaminate substructures.

Adv. Mater. 2018, 1804727

Bidirectional TRIP effect High Entropy A[...]

PDF-Dokument [1.6 MB]

How can bidirectional martensitic transformation lead to hierarchical nanolaminates in high-entropy alloys ?

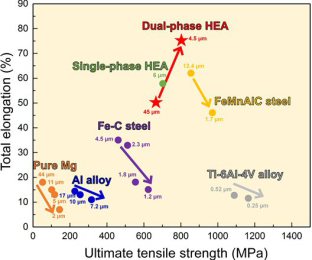

The refinement of microstructural length scales is a very efficient approach to strengthen metallic materials. Conventional methods for refining microstructures generally involve grain size reduction via heavy cold working, often reducing the material’s ductility.

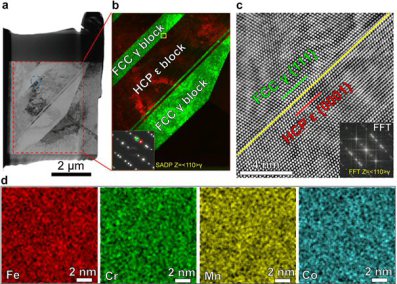

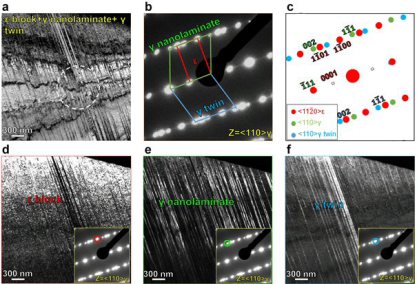

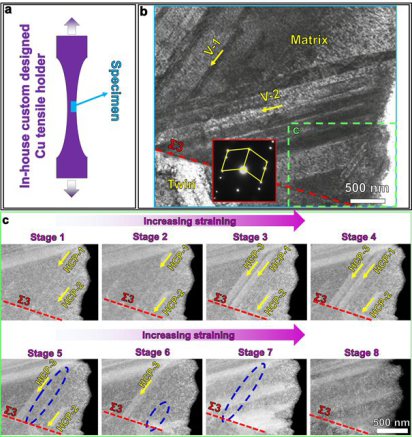

In a high entropy alloy we now observed a novel phenomenon that allows load-driven formation and permanent refinement of a hierarchical nanolaminate structure. This is achieved by triggering both, dynamic forward transformation from a faced-centered cubic (FCC) γ matrix into a hexagonal close-packed (HCP) ε nanolaminate structure and the dynamic reverse transformation from ε into γ.

We refer to this new mechanism as Bidirectional Transformation Induced Plasticity effect (B-TRIP), which is enabled through a near-zero yet positive stacking fault energy of γ. Modulation of directionality in the transformation is triggered by local dissipative heating and local micromechanical fields. The simple thermodynamic and kinetic foundations for the B-TRIP effect render this approach generally suited for designing metastable strong and ductile bulk materials with hierarchical nanolaminate substructures.