Adiabatic heating during plastic straining

Irreversible plastic deformation of metals proceeds by dislocation motion and displacive mechanisms such as mechanical twinning or martensitic transformation. The associated deformation energy is predominantly dissipated via defect motion, leading to a distinct thermomechanical response. In metals, this can result in local temperature increases of up to several hundred Kelvin. For example, Chen et al. (ISIJ, 2007;47) measured overall temperature increases in Fe–Mn–C steels due to the Portevin–LeChatelier effect of about 110°C. Ranc et al. (Mech Mater 2008;40) even observed maximum local temperatures of about 1000°C inside shear bands that formed just before failure during dynamic torsion tests in Ti alloys. Quantifying local dissipative heating is important as it affects thermally activated processes, such as dislocation motion, interface motion, nucleation and strain hardening, or diffusion-related phenomena, such as hydrogen embrittlement. Many of these thermally activated phenomena depend exponentially on the temperature. This means that deformation-driven local heating can lead to strong kinetic deviations from the material behavior that would be expected from the nominal temperature at which a global test takes place. The velocities of lattice dislocations and deformation twins can be high, and in some cases can approach the shear wave velocity. As the friction stress in metals is rate dependent, high shear rates also lead to a high energy release rate and, hence, higher frictional heating when compared to low deformation velocities. The instantaneous dissipative heating that occurs during plastic deformation is adiabatic. This means that the heat generation rate is much larger than the heat transfer rate. Hence, the deformation energy released as heat remains in the strained zone for a short time interval, before spreading via heat conductivity. During this time interval, the released heat can be quantified by temperature-sensitive devices. Thermal imaging has been used to visualize localized plastic effects like shear band motion and the Portevin–Le Chatelier effect in several alloys, registering instantaneous local temperature increases ranged between 0.5 K and 30 K, and overall accumulated temperature increases during testing of 1.5–1000 K.

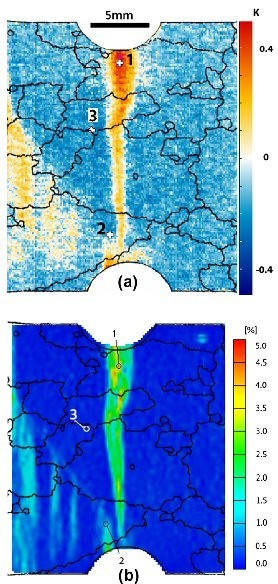

Here we study local deformation and temperature effects associated with mechanical twinning in Fe–3 wt.% Si at room temperature. During tensile testing, two large stress drops occurred. They were ac

Acta-Mater-2012-Adiabatic-heating-twinni[...]

PDF-Dokument [1.9 MB]